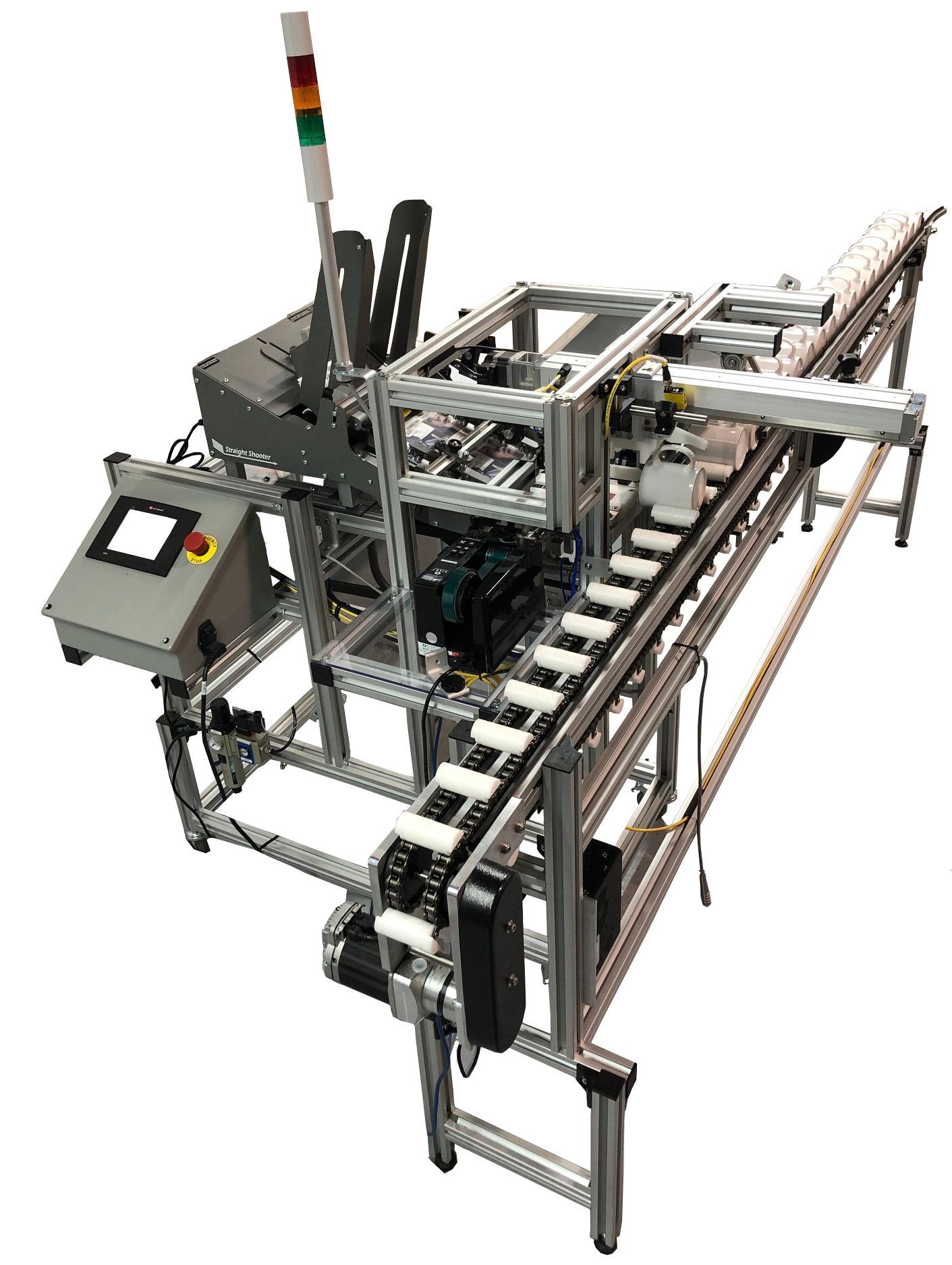

The automatic mug wrap system was designed to wrap 11 & 15 oz. mugs commonly used today.

-

- Estimated to wrap 15+ mugs per minute!

- Operators are needed for placing mugs on and off of the indexing conveyor.

- Robotic options are available for loading and unloading.

- Mug Handle Straightening Mechanism

- Indexing Mug Conveyor

- Print & Apply Labeling System to apply a matching barcode to the bottom of the mug.

- Demand Friction Feeder for Feeding Sublimation Sheets

- Industrial Tape Dispenser x 2

- Sublimation Sheet Barcode Reader with Inline Sheet Reject

- Sheet Tape Application & Mug Wrapping Mechanism

- Sublimation Sheet and P&A Label Barcode Match Verification System with In-Line Mug Reject

- Programmable Logic Controller (PLC)

SMW-AUTO Can Wrap Up to 13 Mugs A Minute!

Mugs are placed into the pockets of the indexing conveyor with handles up. The handle alignment system rotates all handles to the 12 o’clock position. Sublimation sheets are single-fed from a friction feeder and the barcode on the sublimation sheet is read with a barcode scanner. If there is a problem with the barcode (duplicate order, canceled order, no-read, etc.) the sublimation sheet is rejected below, not being applied to a mug, and a new sublimation sheet is fed and scanned. Approved sublimation sheets are fed into the wrap station. Industry-proven tape dispensers feed the precise length of tape, and the tape is applied to the sublimation sheet.

Mugs index to a Print and Apply Labeler to have a matching printed barcode label applied. A linear stepper-driven actuator plucks the coffee mugs off the indexing conveyor and the labeled mugs are moved into the wrapping station. The sheet is lifted making contact with the mug at 6 o’clock. Wrapping arms continue up the circumference of the mug pulling the sheet and pressing tape onto the mug by the handles. The sublimation sheet is taped straight and taught on the mug. The wrap arms retract.

The mug is placed back onto the conveyor. A barcode reader reads the barcode on the sublimation sheet and compares with the barcode label applied to the bottom of the mug, making sure they are identical.

-

- Electrical requirements: 110 VAC, 60 Hz, 5 Amps.

- Air requirements: 80 PSI at 2 CFM.